AURUNA® 559 is used for the very fast deposition of semi-bright to satin fine gold coatings with excellent bonding and soldering properties. The neutral fine gold electrolyte was...

Neutral high-speed electrolyte for selective gold-plating

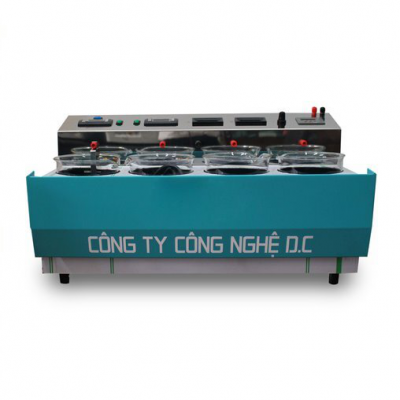

AURUNA® 559 is used for the very fast deposition of semi-bright to satin fine gold coatings with excellent bonding and soldering properties. The neutral fine gold electrolyte was specifically developed for use in high-speed equipment for selective goldplating (spray and flow lines, jet and spot plating).

Maximum applicable current density and therefore plating speed as well essentially depend on the electrolyte agitation at the parts (flow velocity), i.e. on the type of equipment used. A high flow velocity allows a high plating speed. For achieving good adhesion, on nickel and nickel alloys in particular, the parts should be strike gold-plated in the AURUNA® 580 gold strike electrolyte. The layers exhibit outstanding bondability and excellent temperature resistance. They are ductile and smooth and light-yellow even at high layer thickness (greater than 20 μm).

Electrolytes Characteristics

| Electrolyte type | Neutral |

| Metal content | 16 (14 - 16) g/l Au |

| pH value | 7.5 (7.3 - 7.5), measured at 25 °C |

| Operating temperature | 70 (70 - 75) °C |

| Current density range | 10 - 25 A/dm² |

| Plating speed | Approx. 6 - 15 μm/min |

| Anode material | Pt-Ti (type PLATINODE® Pt/Ti) |

Coating Characteristics

| Coating | Fine gold |

| Purity | 99,9 wt. % Au |

| Colour of deposit | Light yellow |

| Brightness | Silk-matt to semibright |

| Hardness | 100 HV |

| Max. coating thickness | Approx. 19 g/cm³ |

Advantages

- Satin fine gold coatings

- For high-speed applications

- High current densities possible (10 – 25 A/dm²)

- High plating speeds (up to 15 μm/min)

- Excellent bonding and soldering properties

- The coatings are RoHS compliant

- Classification according to ASTM B-488-01 Type I-II, Code C-D

Applications

- Semiconductors